Summits for a Sustainable Planet

Our Proprietary Technology

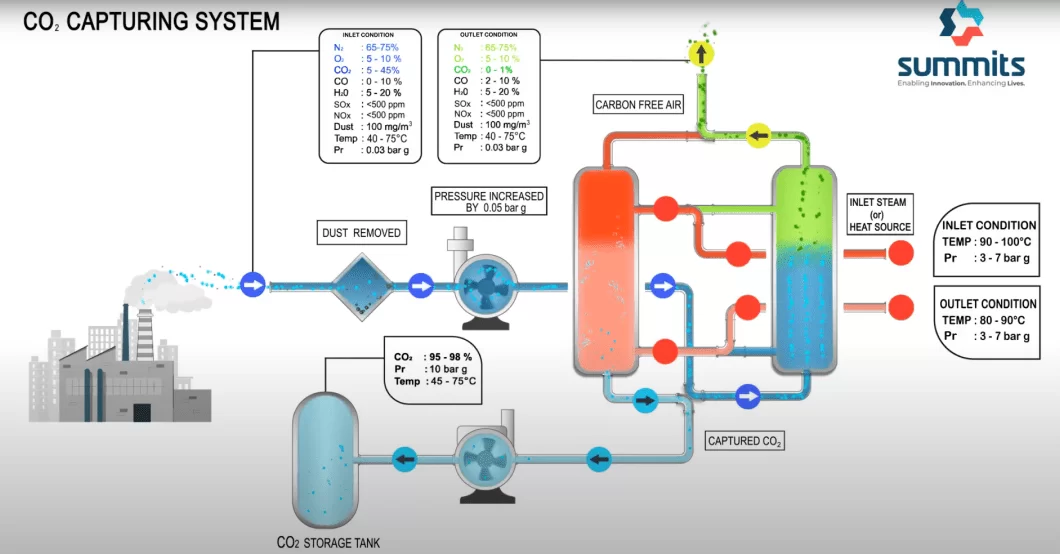

A truly unique and innovative approach to remove CO₂ emissions in an energy efficient way using our low CAPEX swing adsorption technology

Our proprietary carbon capture process uses a series of adsorption and desorption vessels/chambers to capture the CO₂

This process can be applied on emissions from various sources, from gas, coal, cement, refineries, steel plants, waste-to-energy, process industries, biogas upgradation and even direct air capture

Flue gas emissions from the point source can be directly fed into our system at the same pressure and temperature, and the CO₂ gas will be captured and stored in a safe manner

A truly plug and play modular design that translates to next to no human interaction

Our Strength

5+ years of screening and testing different adsorbents and optimizing the reactors for cyclic capture and release of CO₂

27+ years of experience in pressure swing adsorption (PSA) technology and gas generation plants

1000+ cycles completed with CO₂ : N₂ mixtures as feed

200+ cycles completed with biogas obtained from biogas generator and flue gas obtained from burning coal

Optimized energy cost for economic capture of CO₂ in scale up to 20,000 tons/year

Working on stability of adsorbents, recycle and reuse of exhausted adsorbents, improving operating range and various mixtures of feed flue gas

Key Benefits

Our process is not affected by the moisture content of the flue gas

Our process has a wide working range. For example, it can work in high temperatures and low pressure

Gaseous phase process, and hence no process water is needed

No replenishment of corrosive solvents

Single heating step of ΔT = 10 to 15 °C compared to heat-cool-heat steps for amine process

Lower CAPEX compared to commercially available processes

Optimised OPEX compared to commercially available processes

Why Summits?

Unlock Your Business Potential

with Summits

We guarantee substantial savings, operational autonomy, and supply continuity.

Talk to Our ExpertsTogether, let’s innovate to enhance lives. Become a Partner