vibration Table

CMS is packed with support of Vibration Table which saves highpacking density and lowest air consumption.

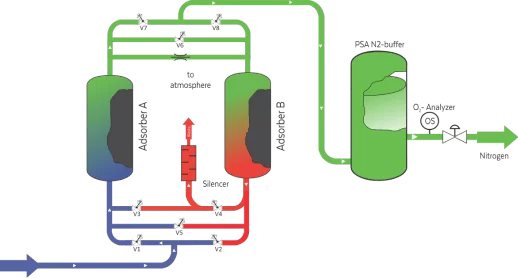

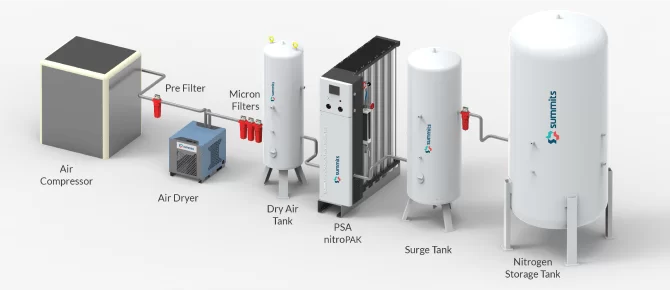

PSA Nitrogen Generators operate on the Pressure Swing Adsorption (PSA) principle to produce a continuous stream of nitrogen gas from compressed air Two towers are filled with carbon molecular sieve (CMS). Pretreated compressed air enters the bottom of the on-line tower and follows up through the CMS.

Oxygen and other trace gasses are preferentially adsorbed by the CMS, allowing nitrogen to pass through. After a pre-set time, the on-line tower automatically switches to regenerative mode, venting contaminants from the CMS.

CMS is packed with support of Vibration Table which saves highpacking density and lowest air consumption.

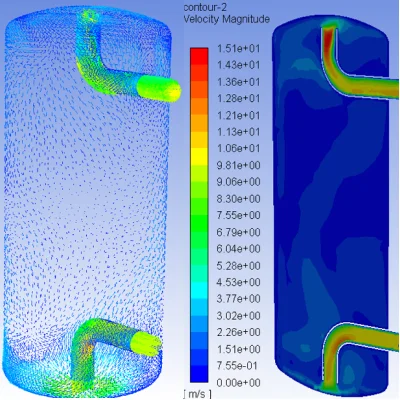

Every parameter affecting the reliability is carefully analyzed and culminated using simulation techniques.

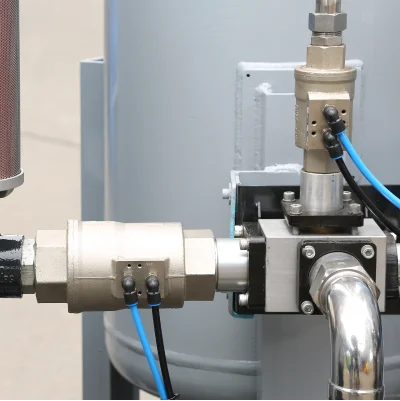

With numerous facilities, controls, maintenance alert and compatible to industries required communication.

Offers potential savings during varying load condition.

With remote monitoring of N2 Purity, Flow & Pressure.

Offers trouble free operation 24 x 7

Helps to ascertain outlet gas purity.

Reduces investment when in need of additional capacity.

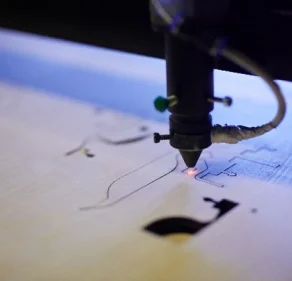

Oxygen presence in the processed air is an uninvited and unwanted element in various process that includes Food processing and Packing, Pharma Industries, Laser cutting, Semi conductor, Heat treatment process, Wine industries, LCMS Laboratory Applications Etc.. Nitrogen in gaseous form with desired purity is an effective and proven inert gas.

We guarantee substantial savings, operational autonomy, and supply continuity.

Talk to Our ExpertsTogether, let’s innovate to enhance lives. Become a Partner