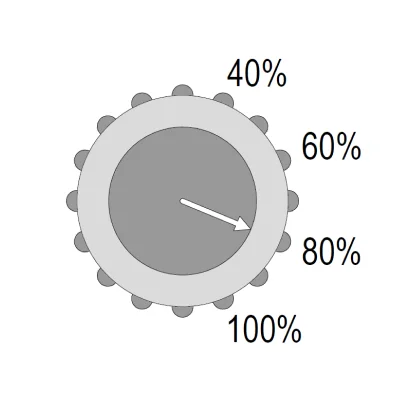

Moisture Indicator

Inbuilt Moisture Indicator helps to ascertain outlet air quality instantly in terms of moisture content.

Guards the lens & other optic system

Moisture Indicator to ascertain outlet air quality

Purge Economizer offers Potential savings

Oil Check apparatus for air quality validation

AVS safeguards your precise equipment at all time

Laser cutting system employ a series of expensive and sensitive optical components including lenses, mirrors, and beam delivery systems. These components are susceptible to damage when exposed to contaminated compressed air.

Particles in the air can erode optical surfaces, while oil and water droplets in the compressed air can form a film on the laser optics, causing beam divergence and distortion, reducing effectiveness of cutting process.

Our LC series Laser dryer offers the perfect solution by delivering clean, dry compressed air round the clock ensuring desired cut quality and accuracy for your components.

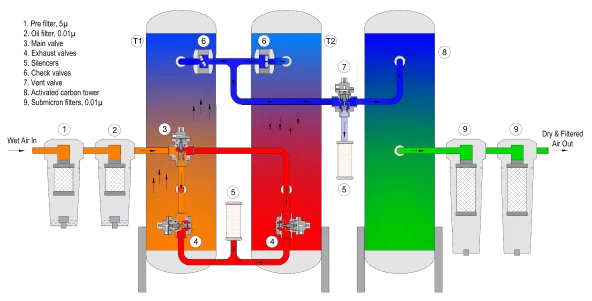

Coalescing filters of 5 micron (1) and 0.01 micron (2) remove bulk moisture and liquid oil from the compressed air. This pre-treated air diffuses to the bottom of the adsorber (T1) and passes through the desiccant bed which adsorbs moisture and dries the air.

Dry air leaving the adsorber (T1), is further treated by Activated carbon water (8) and submicron filters (9). Activated carbon removes traces of oil vapour and submicron filters remove particles down to 0.01 micron making compresses air suitable for laser cutting process. AVS system (7) ensures 100% clean compressed air to the application at all time.

Inbuilt Moisture Indicator helps to ascertain outlet air quality instantly in terms of moisture content.

4-step air purification process with borosilicate depth filter media removes bulk moisture and oil completely.

Oil check apparatus helps to measure the oil content in the outlet air down to 0.1 to 0.2mg/m3.

Activated carbon bed removes oil vapor content down to 0.003mg/m3 and offers technically oil-free air.

We guarantee substantial savings, operational autonomy, and supply continuity.

Talk to Our ExpertsTogether, let’s innovate to enhance lives. Become a Partner