HTM 02-01

Medical Air dryer

SERIES : mLife and mLife Plus

- Capacity : 10cfm to 250cfm

- 4 bar(g) to 12 bar(g)

Precisely manufactured in meeting Medical Grade Standards

mLife and mLife+ Feature

Premium at every stage.

Medical grade air with -46°C ADP as per HTM 02-01

Catalyse Carbon monoxide conversion

Bacteria filter for Absolute retention rate of 0.22μm particle down to 99.9999%

Oil Check apparatus for air quality validation

Auto Change over ensures medical air 24/7

High importance of Medical air in healthcare industries

Medical air is primarily used in hospitals, clinics, and other healthcare facilities for aerosol drug delivery, high flow therapy, mechanical ventilation, neonatal environment control, infant resuscitation, general anaesthesia, and hyperbaric therapy. It is also used for cleaning and drying medical instruments and equipment, powering certain medical tools.

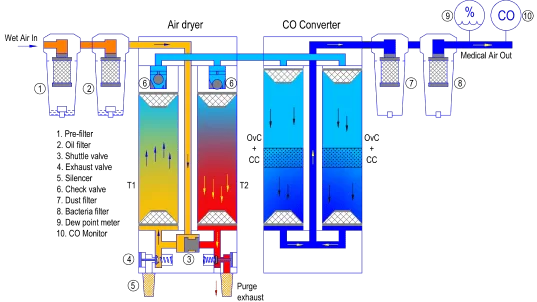

Compressed air to Medical air by mLife+

Coalescing type Pre-filter (1) of 5μ and Oil filter (2) of 0.01μ removes bulk moisture and liquid oil from the compressed air. This pre-treated air diffuses to the bottom of the Tower (T1) and passes through the desiccant bed. This desiccant bed besides adsorbing moisture and dries the air, it also adsorbs CO2. Dry air leaves the Tower (T1) and passes through OvC + CC unit. OvC stands for Oil vapour capturing unit. CC stands for Catalytic converter. As the name implies, OvC adsorbs Oil vapour and CC converts Carbon monoxide to Carbon dioxide. Dust filter (7) of 1μ removes particulates. Bacteria filter (8) filters the air out of microorganisms, such as bacteria, parasites, fungi down to 0.22 micron at 99.9999% efficiency. Thus, ultra-purified medical grade air is ready for utilization.

The desiccant can adsorb only certain quantity of moisture and will reach equilibrium after certain time. It can no longer dries the air to the required dew point and should be regenerated to keep the process continuous. To regenerate the Tower (T1), some partial quantity of dry air coming out of Tower (T2) is diverted to Tower (T1). This Dry air expands to atmospheric pressure and become subsaturated. This subsaturated dry air purges out all moisture from the Tower (T1) and makes it ready for next adsorption.Air flow is diverted to each Tower alternatively by valves and controller.

Meets International Standards

NFPA 99

ISO 7396

ISO 13485

Standards for health care service

ISO 7396, HTM 02-01 & NFPA 99 are the globally recognized standard for assuring high quality health services where it matters most.

Premium at every Stage

Quite operation

Silent and No back pressure which hampers dew point. Corrosion-resistant aluminium end covers for longer life

Large surface area

Pleated Borosilicate depth filter with large surface media at all micro filters offer No Drop in efficiency till its entire life.

Stainless steel

Unsurpassed structural strength and durability. More hygienic and easier to clean than other solid surfaces.

Advanced PLC

Integrated PLC with numerous facilities, Controls, Maintenance alert and compatible to industries required communication protocol. RS485 Modbus, BMS, IOT, Ethernet, Industry 4.0.

Dewpoint dependent system (DDS)

Online dew point meter monitors outlet air dryness 24/7. Dew point based purge ensures right quantity of purge according to end point consumption.

Catalytic Converter

Effectively destroy carbon monoxide ensures patient safety and meets international standards even in most polluted environment.

Uniform Distribution

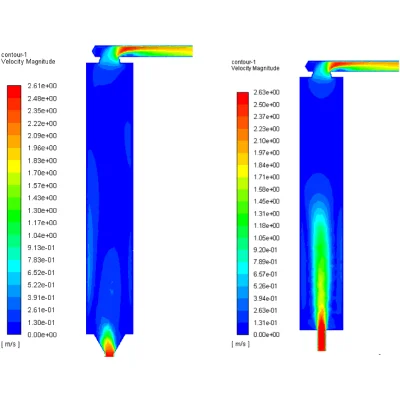

Stainless steel Conical diffusers ensure uniform distribution of compressed air to desiccant bed and supports effective removal of moisture at every milli-meter travel of compressed air during drying process

Longer MTBM

Honed cylinder for piston movement; Double spring for piston retraction; U cup seal for Proportional sealing; PTFE guide ring prevents metallic contact and absorb travers force. All the above extends MTBM (Mean time between maintenance)

Engineered the best

Every parameter affecting the reliability is carefully analyzed and culminated using simulation techniques.

99.9999% Efficiency

Bacteria filter for Absolute retention rate of 0.22μm particle down to 99.9999%

Safety

Online carbon monoxide instrument monitors outlet air CO content 24 x 7 Triggers emergency alarm if CO level exceeds 10 ppm

Monitor effortlessly

Pressure gauge at each adsorber and at In/out assist in ensuring proper functioning of system and to diagnose fault effortlessly.

Oil check apparatus

Oil check apparatus (mLife+) helps to measure the oil content in the outlet air down to 0.1 to 0.2mg/m3

Extended Life

Filtered dry air for actuation of valves ensures longevity of valves operation.

Why Summits?

Unlock Your Business Potential

with Summits

We guarantee substantial savings, operational autonomy, and supply continuity.

Talk to Our ExpertsTogether, let’s innovate to enhance lives. Become a Partner