Engineering for the greater good of humanity is how we see our work. For more than 2 decades, we have been pushing the boundaries of applied science and engineering to make the air functional for business growth and global well-being.

A Global Leader in Compressed Air Dryer / Purification & Gas Generation

OUR OFFERINGS

Tailor-made Products at International Standards

Industrial / CAP Custom Build

HOC Dryer

Industrial / CAP Custom Build

No Split Flow Dryer

Industrial / CAP Custom Build

Nitrogen GeneratorWorldwide installations since 1996.

With a clientele spread across Asia, Europe, the Middle East, the Far East, Africa, and the US, we deliver solutions for the world’s critical air purification and gas generation needs.

Our Machines, Up & Running for Decades

From offering standard and requirement-specific turnkey solutions to providing excellent implementation support and on-site maintenance, we ensure uninterrupted uptime.

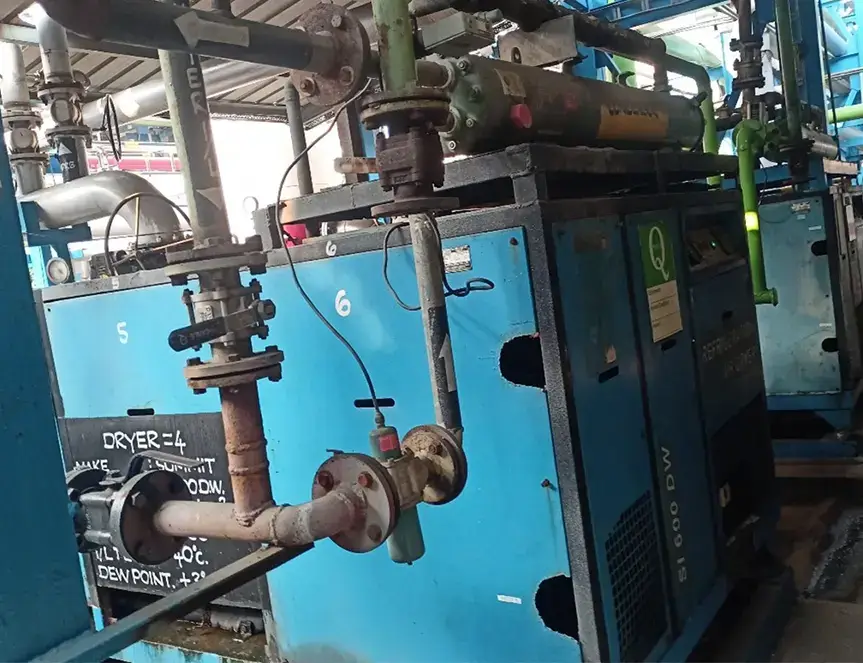

REFRIGERATED AIR DRYER

Capacity : 1750 CFM

Running Since 2012

Delphi TVS Technologies Limited

Chennai

REFRIGERATED AIR DRYER

Capacity : 6600m3/hr at 3.2 bar WP

Running Since 2012

NTPC Limited

Andhra Pradesh

Contributions to

Nation-Building

We actively deliver products and turnkey solutions across various industries such as government and private organizations and projects, across industries like energy, space, defence, infrastructure, transport and logistics, automobile, pharmaceutical, and more.

Contributions to

Combat A COVID-19

During the COVID-19 pandemic, we proactively responded to the emergency needs of the healthcare sector. With 390 hours of continuous production, we delivered medical oxygen generators and medical air purification products through PM Cares Fund.

Standard Product

Our Industrial & Medical Product

Industrial / CAP Standard

Refrigeration Air Dryers

Industrial / CAP Standard

Tex dryer

Industrial / CAP Standard

Heatless Air Dryers

Industrial / CAP Standard

Laser Dryer

Industrial / CAP Standard

Modular Heatless Air Dryer

Industrial / CAP Standard

Micro Filters

Industrial / CAP Standard

Moisture Separator

Industrial / CAP Standard

Timer Auto Drain Valves

Industrial / CAP CAP Standard

Zero Air Loss Drain Valves

Industrial / CAP Standard

Air Receiver

Healthcare

Medical Air dryer

Healthcare

Medical Oxygen Generators

Healthcare

Vacuum FiltersTestimonials

What Our Clients Say

I am using Summits Refrigeration Air Dryers various capacities for my machine shop application, the performance and service supports are good and I am happy with Summits

We have been various capacities Summits Refrigeration and Desiccant Air Dryers since 2010. We are very much satisfied with their technical support. The products are delivering excellent performance

We are using 1250cfm and 500cfm Summits Refrigeration Air Dryers 2 years , we are satisfied with their products

We installed 1650 cfm Summits Refrigeration Air Dryer for our weaving machine application. The product is performing better even in peak summer.

NEWSROOM

What’s New

Blower Reactivated Gas Dryer Supplied for IOCL Panipat

Summits Hygronics has supplied a Blower Reactivated Gas Dryer for the Debutanizer Overhead Gas

MAP Product Launching Programme

The launch session for our innovative MAP Nitrogen Gas Generator was held on Jan 25, 25

"Women’s Health and Hygiene" Awareness Program

On January 4, 2025, we organized a special awareness program on "Women’s Health and Hygiene",

Unlock Your Business Potential

with Summits

We guarantee substantial savings, operational autonomy, and supply continuity.

Talk to Our ExpertsTogether, let’s innovate to enhance lives. Become a Partner